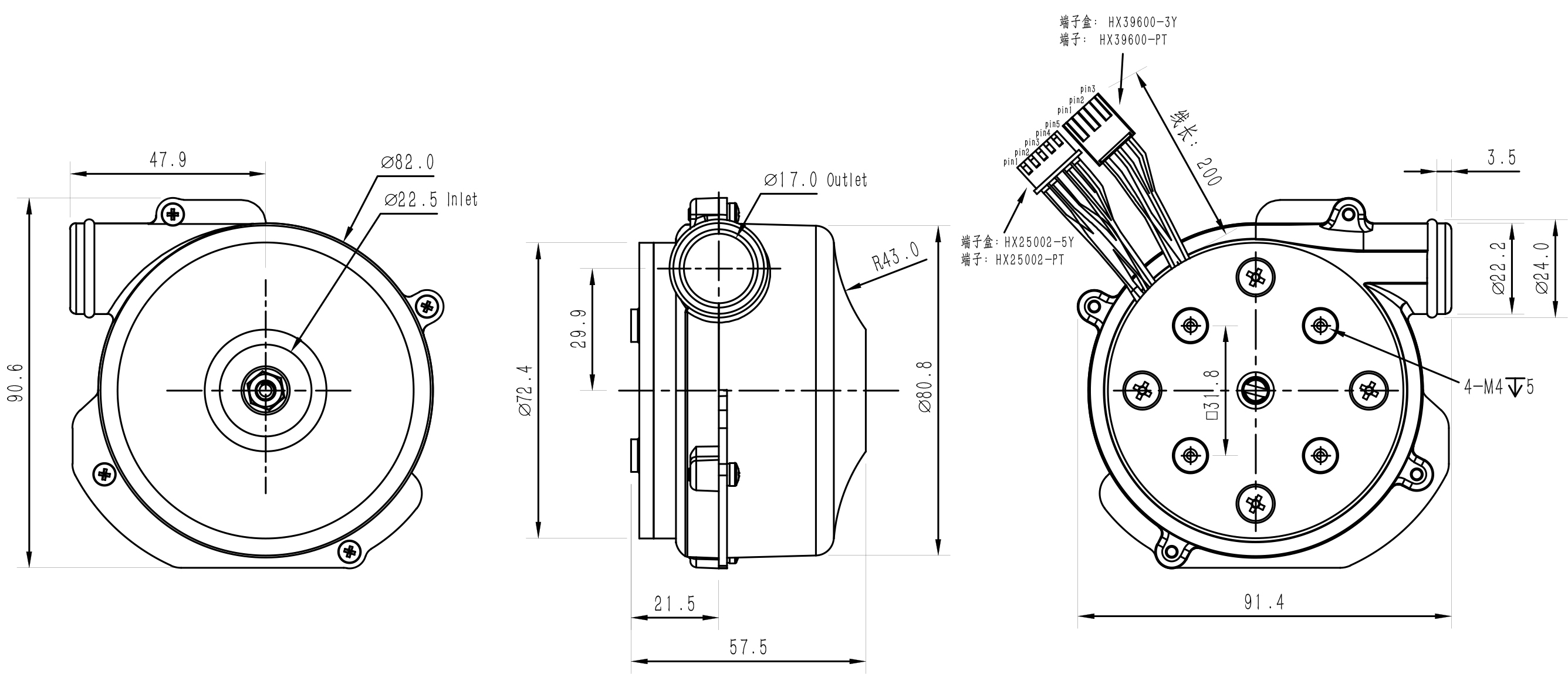

This blower can run at CCW direction only.Reverse the impeller running direction can not change the air direction. Filter onto the inlet to protect the blower from dust and water. Keep the environmental temperature as low as possible to make the blower life time longer.Voltage:24VDC Certification: ce, RoHS, ETL Warranty: 1 Year After-sales Service Provided: Online support Life time(MTTF): >20,000hours (under 25 degree C) Weight: 400 grams Housing material:PC Unit size: 90*90*50mm Motor type:Three Phase DC Brushless Motor Controller: external Static pressure: 8kPaBrand name: Wonsmart High pressure with dc brushless motor Blower type: Centrifugal fan Voltage:24vdc Bearing: NMB ball bearing Type: Centrifugal Fan Applicable Industries:Manufacturing Plant Electric Current Type: DC Blade Material: plastic Mounting: Ceiling Fan Place of Origin:Zhejiang, ChinaWS9250-24-240-X200 blower can reach maximum 44m3/h airflow at 0 kpa pressure and maximum 8kpa static pressure.It has maximum output air power when this blower run at 4.5kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 5.5kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:(1)WS9250-24-240-X200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 15,000hours at 20 degree C environmental temperature (2)This blower needs no maintence (3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily (4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.This blower can be widely used onto air pollution detector,air bed,air cushion machine and ventilators.Q: When can I get the price? A: Usually we quote within 8 hours after we get your inquiry. Q: What’s your MOQ? A: It will be no MOQ, If we have the products in stock. We will discuss the MOQ according to customer’s exact situation. Q: How long is your delivery time?A: The general delivery time is 15-20 days after receiving your order confirmation. Anther, It will only take 1-2 days if we have stock.What is the difference between brushless DC motor and brush motor? DC brushless motor is through the process of electronic commutation, and brushless machine is through the process of brush commutation, so brushless machine noise, low life, as usual brushless machine life in 600 hours as follows, brushless machine life abnormality is determined by bearing life, will span 5000 hours. The brush of electromechanical brush often switches on electromagnetic interference to other electronic devices. Speed control, DC brushless motor through voltage speed regulation, analogy is simple and convenient, but when the speed ratio is low will be limited; DC brushless motor can also be through voltage speed regulation, but also can be used PWM speed regulation method to facilitate speed control at low speed. Energy and speed, mainly depends on the mechanical and electrical parameters of the plan, but the brushes can be converted in a very high power situation, because the arc occurs too large, so that ordinary power will not be too large, I know in the 5P, brushless mechanical and electrical can achieve great power; brush mechanical and electrical will not have very high speed. As the brushes wear out quickly and clearly, the brushless machine may reach a speed of 80,000 rpm/min. Of course, a brushless machine has the advantage of being expensive and easy to operate; a brushless machine is usually much more expensive than an amateur in terms of control. With the continuous maturity of brushless electromechanical control techniques, lower cost of electronic components and people’s moral requirements for product improvement and energy-saving emission reduction pressure, more and more brushless electromechanical and AC electromechanical will be replaced by brushless DC electric mechanical.

This blower can run at CCW direction only.Reverse the impeller running direction can not change the air direction. Filter onto the inlet to protect the blower from dust and water. Keep the environmental temperature as low as possible to make the blower life time longer.Voltage:24VDC Certification: ce, RoHS, ETL Warranty: 1 Year After-sales Service Provided: Online support Life time(MTTF): >20,000hours (under 25 degree C) Weight: 400 grams Housing material:PC Unit size: 90*90*50mm Motor type:Three Phase DC Brushless Motor Controller: external Static pressure: 8kPaBrand name: Wonsmart High pressure with dc brushless motor Blower type: Centrifugal fan Voltage:24vdc Bearing: NMB ball bearing Type: Centrifugal Fan Applicable Industries:Manufacturing Plant Electric Current Type: DC Blade Material: plastic Mounting: Ceiling Fan Place of Origin:Zhejiang, ChinaWS9250-24-240-X200 blower can reach maximum 44m3/h airflow at 0 kpa pressure and maximum 8kpa static pressure.It has maximum output air power when this blower run at 4.5kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 5.5kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:(1)WS9250-24-240-X200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 15,000hours at 20 degree C environmental temperature (2)This blower needs no maintence (3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily (4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.This blower can be widely used onto air pollution detector,air bed,air cushion machine and ventilators.Q: When can I get the price? A: Usually we quote within 8 hours after we get your inquiry. Q: What’s your MOQ? A: It will be no MOQ, If we have the products in stock. We will discuss the MOQ according to customer’s exact situation. Q: How long is your delivery time?A: The general delivery time is 15-20 days after receiving your order confirmation. Anther, It will only take 1-2 days if we have stock.What is the difference between brushless DC motor and brush motor? DC brushless motor is through the process of electronic commutation, and brushless machine is through the process of brush commutation, so brushless machine noise, low life, as usual brushless machine life in 600 hours as follows, brushless machine life abnormality is determined by bearing life, will span 5000 hours. The brush of electromechanical brush often switches on electromagnetic interference to other electronic devices. Speed control, DC brushless motor through voltage speed regulation, analogy is simple and convenient, but when the speed ratio is low will be limited; DC brushless motor can also be through voltage speed regulation, but also can be used PWM speed regulation method to facilitate speed control at low speed. Energy and speed, mainly depends on the mechanical and electrical parameters of the plan, but the brushes can be converted in a very high power situation, because the arc occurs too large, so that ordinary power will not be too large, I know in the 5P, brushless mechanical and electrical can achieve great power; brush mechanical and electrical will not have very high speed. As the brushes wear out quickly and clearly, the brushless machine may reach a speed of 80,000 rpm/min. Of course, a brushless machine has the advantage of being expensive and easy to operate; a brushless machine is usually much more expensive than an amateur in terms of control. With the continuous maturity of brushless electromechanical control techniques, lower cost of electronic components and people’s moral requirements for product improvement and energy-saving emission reduction pressure, more and more brushless electromechanical and AC electromechanical will be replaced by brushless DC electric mechanical.